Attachment can't exceed 30M invalid email address This field is required

You are here: Home » Fully Automatic Paper Bag Making Machine » Multiwall Paper Bag Making Machine

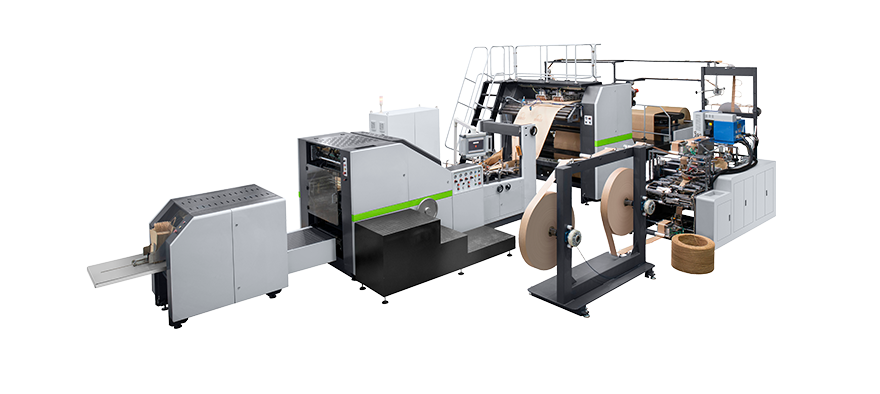

Multi Wall/Layer Paper Bag Making Machine - Rokin Machinery

The multiwall or multi-layer paper bag is a well-known packaging method in different industries because of its strength, durability, customizability, moisture resistance, reusability, and recyclability. They commonly have several layers of kraft paper, reinforced with a plastic liner to provide security against dampness and punctures.

Rokin multiwall paper bag machine is designed to streamline and enhance the bag manufacturing process to increase production efficiency. It can produce multi-layer paper bags of different sizes and thicknesses and accurately and precisely perform printing, laminating, cutting, and folding functions..

Machine Features and Benefits

Features

- Robust Construction

Sturdy frame and durable components ensure long-lasting performance.

- High Production Capacity

Maximizes output to meet high-demand requirements.

- Versatile Paper Size Range

Allow bag dimensions and designs to be flexible.

- Easy Operation

Our machine simplifies bag manufacturing with an intuitive interface and user- friendly controls.

- Low Maintenance

Reduces downtime and operational costs

Benefits

- Superior Bag Quality

- Increased Efficiency

- Cost Savings

- Customizable Options

Satisfy customers with precise dimensions, strength, andreliable sealing.

Our multiwall paper bag-making machines accelerate manufacturing by automating bag production.

Optimized material usage and energy efficiency minimize waste and lower production costs to enhance profitability.

Offering customizable features such as printing capabilities and handle attachments allow for diverse customer requirements.

Multiwall Paper Bag Machine Specifications

The Multiwall Paper Bag Machine specifications conclude a speed range of up to 280 bags per minute, a bag width range of 80-220mm, and a bag length range of 155-500mm. The machine is also designed with an automatic web guiding system, a tension control system, and a touch screen control panel for easy operation. Other features include a hydraulic reel stand, an auto-counting system, and a paper roll clamping system.

With these specifications, the Multiwall Paper Bag Machine provide an exceptional level of quality and productivity in the manufacturing of Multiwall paper bags.

Paper bag cutting length (C)

220-430mm

260-530mm

260-530mm

350-810mm

350-810mm

Paper bag width (W)

80-190mm

130-330mm

180-450mm

220-450mm

220-550mm

Paper bag bottom width (H)

50-100mm

70-180mm

90-180mm

100-250mm

100-250mm

Paper roll width

290-610mm

400-1050mm

570-1290mm

670-1430mm

670-1630mm

Paper thickness

45-120g/m2

60-160g/m2

60-160g/m2

80-160g/m2

80-160g/m2

Max. speed

150-200pcs/min

150-200pcs/min

150-180pcs/min

150-180pcs/min

120-180pcs/min

Power

8KW

8KW

8KW

15KW

15KW

Dimension

L9200*W1600*H1800mm

L10000*W2100*H2100mm

L10000*W3000*H2100mm

L11000*W3200*H2400mm

L11000*W3800*H2400mm

Weight

5000 KGS

8500 KGS

10000 KGS

12000 KGS

14000 KGS

Bag Samples Produced By Rokin Multiwall Paper Bag Machines

Benefits of Rokin Machines

Food and Agricultural

Provide reliable protection and

moisture resistance to maintain the quality and freshness of the products, including rice, flour, grains, sugar, nuts, coffee beans, tea, animal feed, etc.

Cosmetics and Personal Care

Suitable for packaging cosmetics, skincare products, shampoos, body washes, etc. Through printing and design, enhancing brand marketing

and product presentation.

Construction Materials

Offer strength and durability and accommodate various industrial and transportation applications, such as packaging cement, chemicals,powdered materials, and more.

Electronics Product Packaging

Multiwall paper bags can also package batteries, accessories, wires, etc. They provide eco-friendly, economical, and proper protection for electronic items.

FAQs About Multiwall Paper Bag Making Machines

What is a multiwall paper bag making machine?

A multiwall paper bag making machine is a specialized industrial machine that manufactures multi-layered paper bags. These machines are designed to efficiently produce bags used in various industries, such as shopping, food packaging, agriculture, etc.

What are the critical components of a multiwall paper bag making machine?

The components of a multiwall paper bag making machine typically include a paper reel stand, a printing unit, a bag forming section, a glue application system, and a bag stacking and delivery system. These components work together to transform paper rolls into finished multiwall bags.

What types of bags can be produced using multiwall paper bag making machines?

Multiwall paper bag making machines can produce a wide range of bags, such as flour bags, animal feed bags, clothes bags, and other similar types. These machines can accommodate various bag sizes, designs, and printing options to meet specific customer requirements.

What are the advantages of using multiwall paper bags?

Multiwall paper bags offer several advantages, including high strength and durability, good moisture resistance, recyclability, and cost-effectiveness. They are an environmentally friendly alternative to plastic bags and are widely used for packaging different products.

Are multiwall paper bag making machines customizable?

Yes, multiwall paper bag making machines can be customized to suit specific manufacturing needs. Depending on your requirements, these machines can be tailored to accommodate different bag sizes, handle types, printing options, and other customizations.

How can I maintain and troubleshoot a multiwall paper bag making machine?

Proper maintenance is crucial for the smooth operation of multiwall paper bag making machines. It involves regular cleaning, lubrication, and inspection of various components. In case of any issues or breakdowns, it's recommended to refer to the machine's manual or consult a qualified technician for troubleshooting and repairs. Rokin provides professional services for paper bag making machines. If you need help with our machine, we will reply asap.

What are the factors to consider when choosing a multiwall paper bag making machine?

When selecting a multiwall paper bag making machine, it's important to consider factors such as production capacity, bag size and design flexibility, ease of operation, maintenance requirements, after-sales support, and overall cost. Evaluating these factors will help you choose a machine that aligns with your production goals.

How Can I Get Started?

To get started, firstly reach out to a reputable supplier or manufacturer of recycled paper bag manufacturing machines. They can suggest machine options for your needs, and assist with installation and training. Rokin Machinery has manufactured types of paper bag making machines since 1997, providing professional products and services for worldwide customers.