The RKHF-550T is a fully automatic paper bag machine for efficiency and precision. It uses a rolling inflatable shaft and a hydraulic automatic feeding system for seamless operation. It boasts a magnetic powder controller and a servo-driven correction system for accurate alignment, complemented by an ultrasonic sensor for exact side corrections. The hydraulic system enables quick sheet roller changes, while the automatic gluing system allows for direct adjustments of glue volume and placement. With an integrated tube-forming structure, the RKHF-550T ensures consistent bag quality. It also includes a SICK color mark system from Germany, a high-performance Yaskawa servo motor from Japan, an automatic lubrication system, and an automated collecting system for superior productivity. This machine is designed for businesses seeking to enhance their paper bag production with state-of-the-art automation.

| Features

The RKHF-550T is a fully automatic paper bag machine that comes with several features that make it stand out from the competition.

One of its key features is its ability to produce twisted handle bags, which are sturdy and easy to carry.

Another great feature of this machine is its high production capacity. It can produce up to 150 bags per minute, making it ideal for businesses with high demand.

The RKHF-550T also has an automatic tension control system, which ensures that the bags are made with consistent quality and reduces waste material. Additionally, it comes equipped with a touchscreen interface that makes it easy to operate and adjust settings as needed.

This machine is also versatile in terms of the types of paper it can work with. It can process various types of paper including kraft paper, coated art paper, white cardboard, and more.

| Technical Sheet

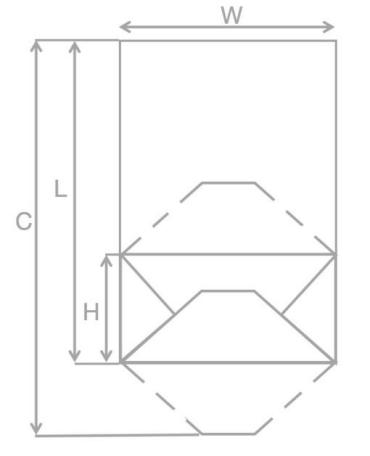

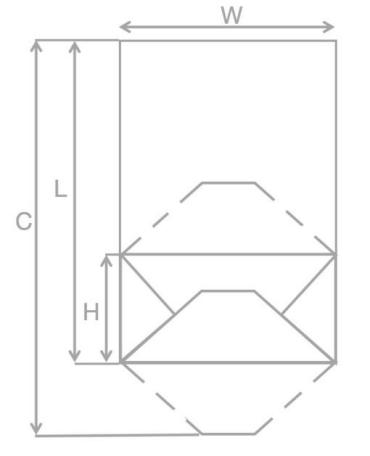

| Model | RKHF-550T |

| Paper bag cutting length (C) | 350-810mm(without handle) 350-710mm(with handle) |

| Paper bag width (W) | 220-550mm |

| Paper bag bottom width (H) | 100-250mm |

| Paper roll width | 670-1630mm |

| Paper thickness | 80-160g/m2(with handle) 60-160g/m2(without handle) |

| Max. speed | 120-200pcs/min |

| Handle rope height | 90-100mm |

| Twisted handle diameter | Dia 3-4mm |

| Handle patch length | 190mm |

| Handle patch width | 40-53mm |

| Handle Height(with sheet) | 130-153mm |

| Power | 30KW |

| Dimension | L14300*W4800*H3000mm |

| Weight | 23000KGS |

| Working Principle

The RKHF-550T Full Automatic Paper Bag Machine with Twisted Handle operates on a simple yet highly effective working principle. The machine is designed to automatically feed paper sheets, apply glue and fold them into the desired shape of the bag.

Firstly, the machine feeds paper sheets from a roll or stack and cuts them into specific sizes using an accurate cutting system. Then, it applies glue along precise lines where necessary for folding.

Next, the folded bags are pressed by rollers to ensure that they have crisp edges and maintain their structure. After this process, twisted handles can be added to each bag as required by feeding pre-cut handle ropes through a twisting mechanism.

Once all these processes are complete, the finished bags are outputted in stacks ready for use or further packaging. This entire process is fully automated and significantly reduces labor costs while increasing production efficiency.

This working principle ensures that every aspect of bag-making is streamlined to reduce waste materials while producing high-quality bags quickly and efficiently.

| Partner

To ensure the highest quality and service for our customers, we have partnered with some of the best suppliers in the industry. Our paper bag machines use top-of-the-line components from well-known brands such as Siemens, Schneider Electric, and Mitsubishi. We also work closely with our partners to stay up-to-date on the latest technological advancements.

In addition to our supplier partnerships, we value strong relationships with our customers. We strive to provide personalized attention and support throughout the entire process - from initial consultation to after-sales service. We are committed to working together with each customer to find a solution tailored specifically to their needs.

Rokin's RKHF-450BF Full Automatic Paper Bag Machine is an excellent choice for businesses looking for high-quality paper bag production capabilities. With its range of features and advanced technology, it can help streamline operations and increase efficiency while producing top-notch bags every time. Contact us today for more information or request a quote!

| FAQ

Q: Is the RKHF-550T Full automatic paper bag machine with twisted handle easy to operate?

A: Yes, it is very user-friendly and can be operated by anyone with basic training.

Q: Can this machine create bags in different sizes?

A: Yes, it has adjustable parameters that allow for various bag sizes to be produced.

Q: What kind of materials can be used in this machine?

A: This machine works well with a variety of materials such as kraft paper, coated paper, art paper, and laminated paper.

Q: Is it possible to customize bags according to specific design requirements?

A: Yes, customization options are available. The machine comes equipped with a digital touch screen which allows for easy programming and customization settings.