The RKHF-450BT Full automatic paper bag machine with twisted handle is a highly efficient and versatile piece of equipment. It boasts an impressive production capacity of up to 120 bags per minute, making it ideal for businesses that require high-volume output.

| Machine feature

One notable feature of the machine is its ability to produce paper bags with twisted handles, which adds an attractive and functional element to the packaging. Additionally, the machine can produce bags in various sizes ranging from small to large, giving businesses flexibility in their product offerings.

Another advantage of this machine is its fully automated operation. This means that minimal human intervention is required during production, reducing labor costs and increasing efficiency. The built-in control system also ensures precision and consistency in bag production.

In terms of materials used, the RKHF-450BT can work with a variety of papers including kraft paper, art paper, whiteboard paper, and laminated paper. This versatility allows businesses to choose the best material for their product needs while maintaining environmentally friendly practices.

This full automatic paper bag machine offers numerous benefits such as increased productivity, cost savings on labor expenses, and materials usage options. It's a great investment for any business looking to streamline their operations while still producing quality products with unique features like twisted handles on each bag produced by this equipment!

| Technical Sheet

| Model | RKHF-450BT |

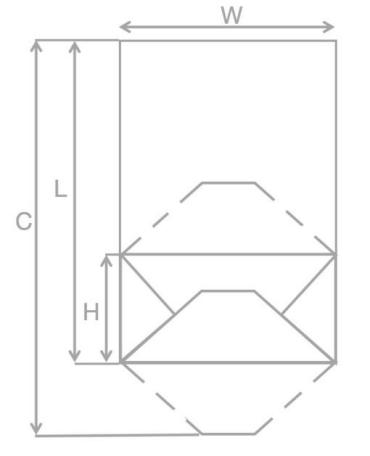

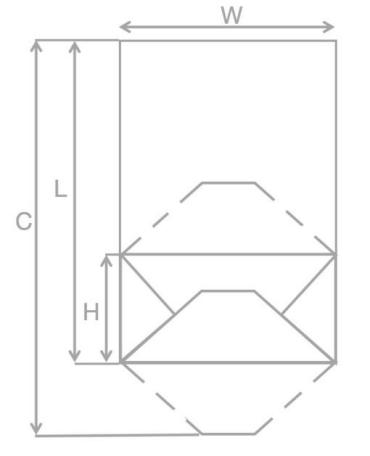

| Paper bag cutting length (C) | 350-810mm(without handle) 350-710mm(with handle) |

| Paper bag width (W) | 220-450mm |

| Paper bag bottom width (H) | 100-250mm |

| Paper roll width | 670-1430mm |

| Paper thickness | 60-160g/m2(without handle) 80-160g/m2(with handle) |

| Max. speed | 120-200pcs/min |

| Twisted handle diameter | 3-4mm |

| Handle patch length | 190mm |

| Handle patch width | 40-52mm |

| Handle Height(with sheet) | 130-152mm |

| Power | 30KW |

| Dimension | L14300*W4800*H3000mm |

| Weight | 19500 KGS |

| Equipment Details

The RKHF-450BT paper bag machine is a fully automatic and highly efficient piece of equipment that can produce up to 220 bags per minute. It features an advanced control system, which allows easy adjustments to the size and length of the bag being produced.

This machine has a unique twisted handle function that adds value and convenience to your paper bags. The twisted handle feature ensures that your customers have a comfortable grip on their shopping bags while also making them look stylish.

One of the standout features of this equipment is its low noise production level, thanks to its advanced technology. Moreover, it comes with an auto-lubrication system that ensures smooth operation while reducing maintenance costs.

Its compact design takes up minimal floor space in any factory setting. Plus, it requires minimal operator input once set up correctly, helping you increase productivity without additional workforce requirements.

The RKHF-450BT full automatic paper bag machine with twisted handle provides fast production speeds with high-quality results for maximum efficiency in your business operations.

The RKHF-450BF is an advanced fully automatic paper bag machine with a flat handle, ideal for creating mid to large-sized paper bags efficiently. It integrates functions like side gluing, roll folding, cutting, bottom forming, and collecting into one seamless process. Its automation capabilities significantly reduce labor costs while enhancing production speed and precision, making it a formidable choice for businesses looking to optimize their packaging process. With its robust design and user-friendly operation, it stands out as a reliable investment for quality and efficiency.

| Technical Sheet

| Model | RKHF-450BF |

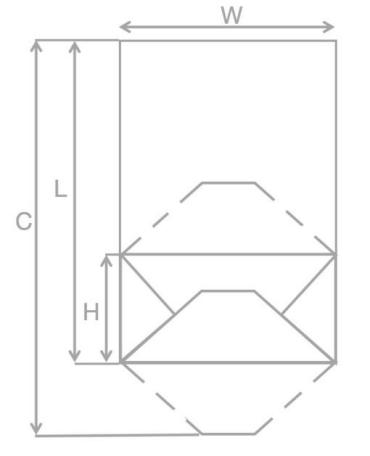

| Paper bag cutting length (C) | 350-810mm(without handle) 350-710mm(with handle) |

| Paper bag width (W) | 220-450mm |

| Paper bag bottom width (H) | 100-250mm |

| Paper roll width | 670-1430mm |

| Paper thickness | 60-160g/m2(without handle) 80-160g/m2(with handle) |

| Max. speed | 120-200pcs/min |

| Flat handle width | 12mm/15mm(choose one size) |

| Handle patch length | 152mm |

| Handle patch width | 40-52mm |

| Handle Height(with sheet) | 40-50mm |

| Power | 30KW |

| Dimension | L14300*W4800*H3000mm |

| Weight | 19500 KGS |

| Machine Features

The RKHF-450BF Full Automatic Paper Bag Machine with Flat Handle is an innovative solution for businesses that require high-quality paper bags. This machine offers a range of features that make it stand out from the competition.

One of the most notable features of this machine is its fully automatic operation. The entire bag-making process, including handle attachment, is automated, which reduces labor costs and increases productivity. Additionally, the machine can produce up to 220 bags per minute, making it ideal for high-volume production.

Another key feature of the RKHF-450BF is its ability to produce bags with flat handles. These handles are comfortable and easy to hold, which makes them popular among consumers. The machine also has a wide range of customization options available so businesses can create unique designs and branding on their bags.

The RKHF-450BF also boasts an advanced control system that ensures precise bag formation and consistent quality throughout production runs. This reliability minimizes waste and maximizes profits by reducing errors in production.

The combination of automation, customization options and precision controls make the RKHF-450BF Full Automatic Paper Bag Machine with Flat Handle an excellent choice for businesses looking to streamline their paper bag production process while maintaining high levels of quality output.

| Application

The RKHF-450BF fully automatic paper bag machine with flat handle is versatile in a wide range of applications. Whether you're looking to produce bags for retail, food service, or other industries, this machine has got you covered. For example:

1. Grocery bags. With its flat handle design and high-speed capabilities, this machine makes it easy to create sturdy and reliable bags that are perfect for carrying everything from fresh produce to canned goods.

2. Brand bags. By using this machine to create personalized paper bags with your company's logo or branding message, you can enhance your brand recognition and make a lasting impression on your customers.

| Partner

To ensure the highest quality and service for our customers, we have partnered with some of the best suppliers in the industry. Our paper bag machines use top-of-the-line components from well-known brands such as Siemens, Schneider Electric, and Mitsubishi. We also work closely with our partners to stay up-to-date on the latest technological advancements.

In addition to our supplier partnerships, we value strong relationships with our customers. We strive to provide personalized attention and support throughout the entire process - from initial consultation to after-sales service. We are committed to working together with each customer to find a solution tailored specifically to their needs.

Rokin's RKHF-450BF Full Automatic Paper Bag Machine is an excellent choice for businesses looking for high-quality paper bag production capabilities. With its range of features and advanced technology, it can help streamline operations and increase efficiency while producing top-notch bags every time. Contact us today for more information or request a quote!