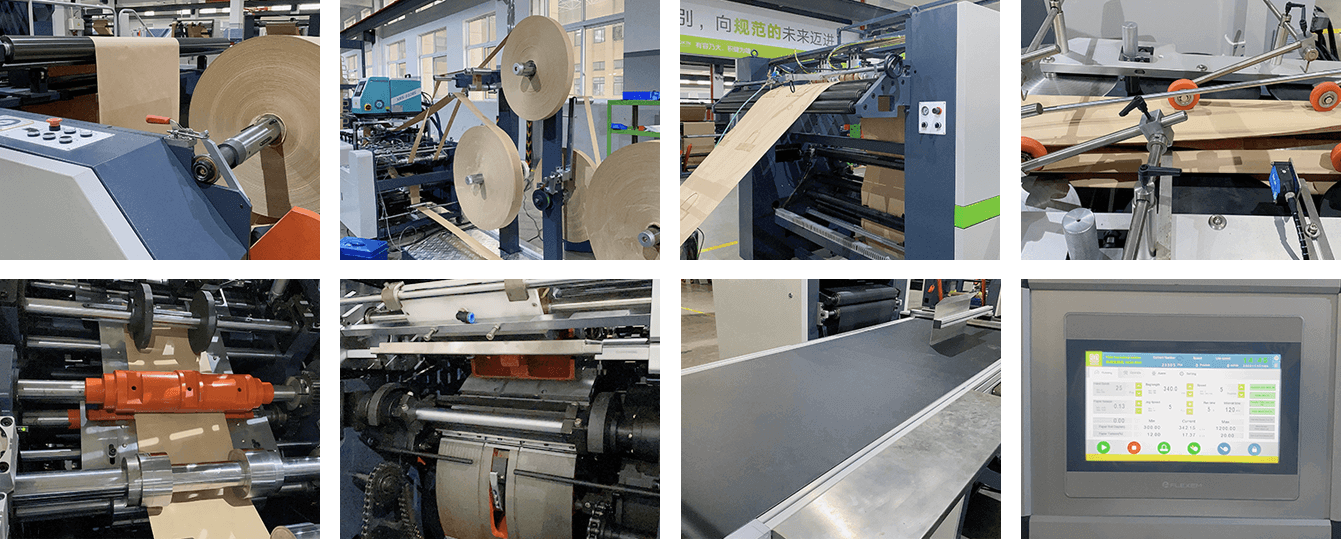

A fully automatic paper bag making machine is a sophisticated piece of equipment designed to automate the entire process of paper bag production. It integrates various mechanical, electrical, and pneumatic components to perform a series of precise operations, from feeding the raw material to forming finished paper bags. Let's break down the working process of a typical fully automatic paper bag making machine:

1. Raw Material Handling

The process begins with the loading of the raw material, typically a roll of paper, into the machine.

The paper roll is mounted on a shaft or roller system, and the leading edge of the paper is threaded through the machine's feeding mechanism.

2. Printing (Optional)

If the machine is equipped with printing capabilities, the paper may pass through a printing unit where custom designs, logos, or text are printed onto the paper.

Printing is often done using flexographic or offset printing methods, allowing for high-quality, customizable bag designs.

3. Cutting and Creasing

As the paper enters the machine, it passes through a cutting and creasing unit where the paper is cut to the desired length for each bag and creases are made to facilitate folding.

Precision cutting ensures consistent bag dimensions, while creasing enables clean, uniform folds in the paper.

4. Folding and Gluing

The cut and creased paper then moves to the folding and gluing section of the machine.

Here, the paper is folded along the crease lines to form the basic structure of the bag.

Adhesive is applied to the edges of the paper to secure the folds and create a strong, durable bond.

Various folding configurations can be achieved depending on the desired bag style, such as flat bags, gusseted bags, or shopping bags.

5. Bottom Forming and Sealing

For bags with a sealed bottom, the machine forms the bottom of the bag using a series of folding and sealing operations.

The folded bottom of the bag is sealed using heat or adhesive to create a secure closure.

Optional reinforcements, such as cardboard inserts or bottom patches, may be added to enhance the bag's strength and stability.

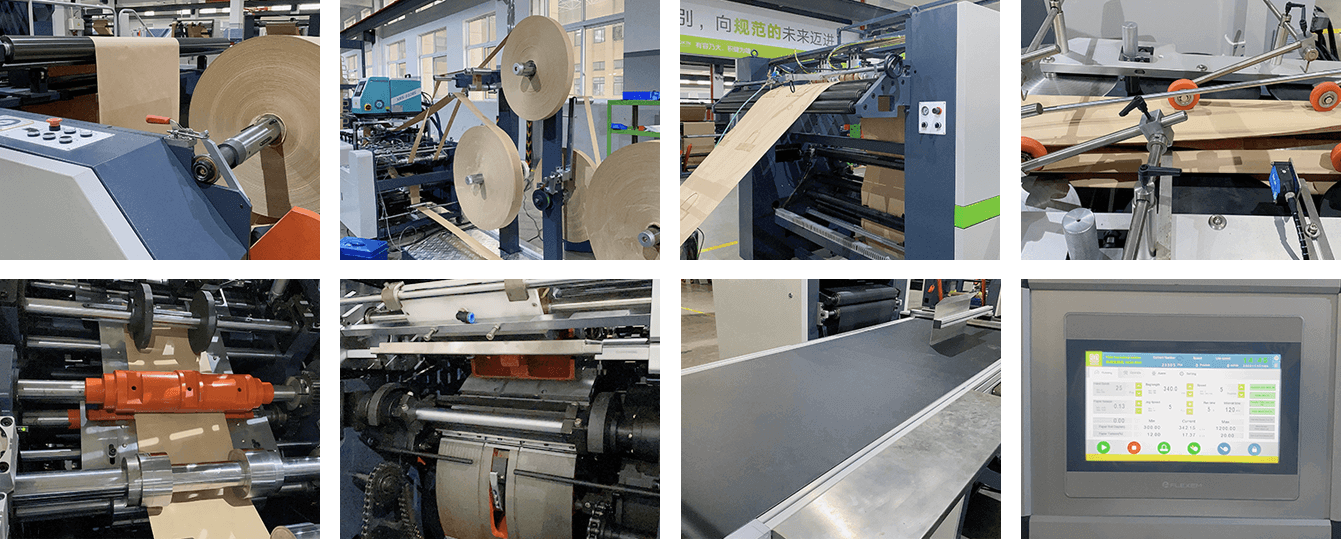

6. Bag Discharge and Stacking

Once the bags are formed and sealed, they are discharged from the machine onto a conveyor belt or stacking platform.

Depending on the machine's configuration, the bags may be stacked in piles or delivered in a continuous stream for further processing or packaging.

Automatic stacking mechanisms ensure neat and orderly stacking of finished bags, ready for packaging or distribution.

7. Quality Control and Monitoring

Throughout the production process, the machine's control system monitors various parameters such as bag dimensions, alignment, and printing quality.

Sensors and detectors are used to detect any defects or irregularities in the paper or finished bags, triggering automatic adjustments or shutdowns if necessary.

Quality control measures ensure that only high-quality bags meeting the specified standards are produced, minimizing waste and maximizing efficiency.

8. Maintenance and Servicing

Regular maintenance and servicing are essential to keep the fully automatic paper bag making machine operating at peak performance.

Maintenance tasks may include cleaning, lubrication, inspection of worn parts, and calibration of sensors and controls.

Scheduled maintenance intervals and preventive measures help prolong the machine's lifespan, reduce downtime, and ensure reliable operation.

A fully automatic paper bag making machine operates through a series of sequential steps, from raw material handling to bag formation, printing, and stacking. By integrating advanced automation, precision engineering, and quality control measures, these machines offer superior efficiency, consistency, and versatility in paper bag production. Want to experience today? Contact us freely. Rokin expert team is always ready to provide customized paper bag making solutions.